НАЗНАЧЕНИЕ:

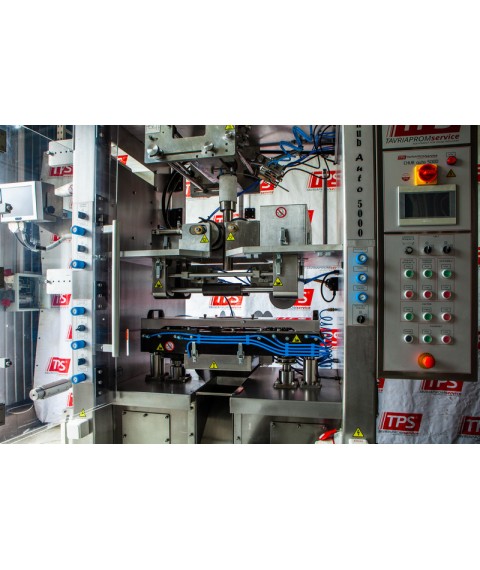

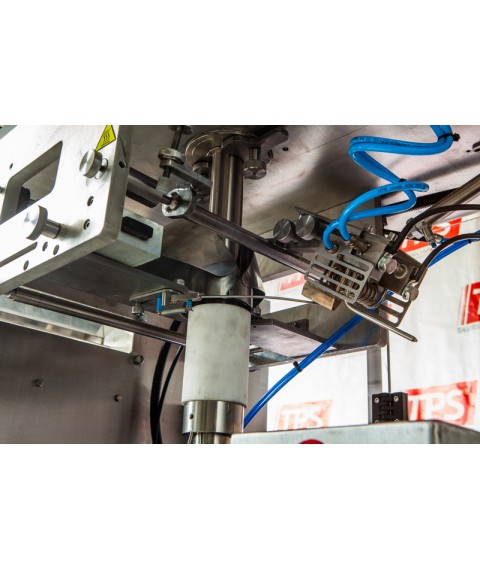

Автомат ЧА-5000 предназначен для фасовки жидких и вязких пищевых и непищевых масс в упаковку типа “ЧАБ” с самостоятельным формированием полимерного рукава из рулона пленки с последующим наполнением его продуктом, с формированием клипсы из бобины алюминиевой проволоки, заклипсовыванием краев батона и отводом готовой продукции из зоны производства.

Производительность - до 100 упаковок/мин

ПРИМЕНЯЕТСЯ ДЛЯ ФАСОВКИ ТАКИХ ПРОДУКТОВ:

Майонез;

Сливочное масло, маргарин, спреды;

Творожные массы, плавленый сыр; десерты; мороженое;

Кондитерские глазури;

Сгущенное молоко (в т.ч. вареное);

Паштеты; фарши;

Заливные (в т.ч. с твердыми включениями);

Различные клеи, бытовая химия и т.п.

ПРЕИМУЩЕСТВА:

Применение данного оборудования в производстве обеспечивает автоматизированную, качественную и быструю фасовку продуктов в удобную для последующего использования потребителем упаковку.

Автомат разработан на базе прототипов ведущих европейских производителей с доработкой основных узлов, с применением собственных иженерно-конструкторских разработок.

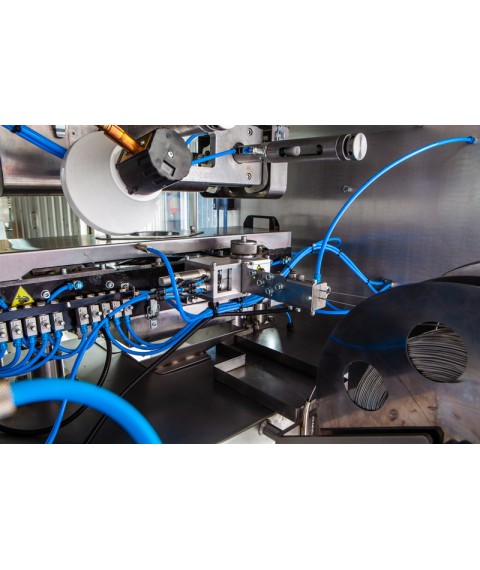

Применение пневматического вала, а также пневматического тормоза узла протяжки пленки позволяет исключить растяжения пленки, повреждения печати, разбежности в размерах упаковки, тем самым минимизируя количество бракованной продукции.

Узел запайки вертикального шва с удобными регулировками позволит быстро и легко перенастроить автомат на различные виды пленок.

Применение дополнительного механизма удаления продукта с хвостиков тубы позволит сделать упаковку привлекательной для потребителя.

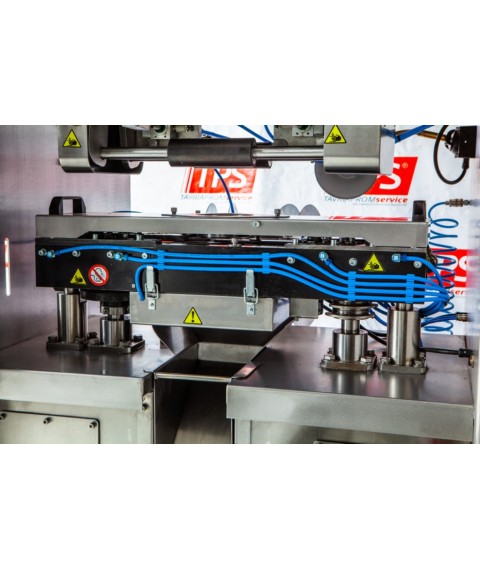

Быстроразборная конструкция узла клипсования. Узел клипсования является самым сложным и самым ответственным узлом автомата. Состоит из большого количества деталей, подвергающихся трению, и являющихся расходными. Данная модернизация позволяет выполнить монтаж/демонтаж узла в сборе в считанные секунды, легко и быстро заменить любую деталь.

Применение высокоточного оборудования для механической и термической обработки при производстве деталей позволяет существенно сократить количество бракованной продукции (брак при формировании клипсы, бой пленки при клипсовании и т.п.), увеличить срок эксплуатации автомата, а также сократить частоту замены быстроизнашиваемых деталей (пуансон, толкатель, матрица, нож, лепесток).

Быстросъемная масляная ванна основного привода предоставляет удобный доступ для визуального контроля и обслуживания.

Простая переналадка на разные форматы. Занимает 15-20 минут.

Системы защиты от заклиниваний, падения уровня масла, попадания посторонних предметов в зону фасовки.

Самодиагностика с выводом информации о режимах работы и ошибках на сенсорный дисплей.

Компактная конструкция, привлекательный внешний вид, высокая степень безопасности оператора.

Подробнее ознакомиться с данным предложением по ссылке

НАШИ КОНТАКТЫ:

г. Херсон, ул. 9-я Восточная, 5

тел.: +38 (067) 552-1110

тел.: +38 (067) 553-1402

sales@tavrproms.com

www.tavrproms.com

YouTube

* Внимание. Описание товара может быть получено путем машинного перевода.

| Характеристики |

| тип управления |

автомат |