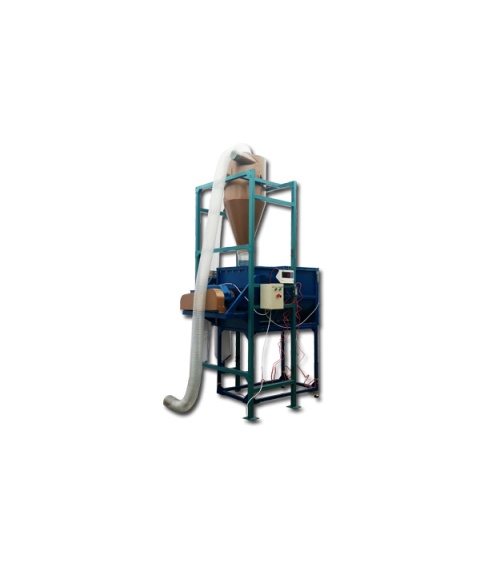

Motor capacity: 7,5 kW

Hopper capacity: 1,5 m3

Yield capacity: 2-5 t/h

Weight: 700 kg

Dimensions: 2900*950*1300 mm

Horizontal feed mixer 1.5 m3 - the best option for high-performance granulation lines. It is also possible to use bulk feed in manufacturing complexes at large farms for the cultivation of poultry and other agricultural animals. The product is equipped with a 7.5 kW motor. At the request of the client, we add weight sensors, an oil injection system and automation. 1 year warranty, there is post-warranty service.

Features of the horizontal feed mixer

Among other models, this equipment stands out:

- three-stage cylindrical gearbox with high torque. It guarantees long uninterrupted operation of the product;

- dust extraction suction system. 99% of the feed particles formed during operation are captured and can be used for granulation. Dust removal ensures that the equipment does not worsen the working conditions of the operator and does not affect his health;

- automatic timer to turn on the reverse. The user can arbitrarily adjust the rotation time of the mixing element in one and the other direction;

- a time switch that automatically turns off the device at the end of the mixing cycle. The duration of the cycle is 5-10 minutes. It increases with increasing volume of the hopper;

- a small gap between the turns of the mixing element and the walls of the hopper. This allows you to guarantee uniformity of the mixture up to 96% at a humidity of up to 15%, regardless of the number of types and proportions of the ingredients used.

Available feed mixer modifications

The 1.5 m3 mixer can be equipped with additional functions:

| - The oil injection system through special nozzles in the hopper. It helps to prepare the mixture that is optimal for granulation without opening the hopper. It is necessary in cases when the raw material does not contain a sufficient amount of binders for the formation of dense granules. The system includes a sealed oil tank, the volume of which can be chosen by the client. If you plan to operate the line in a cold room, we supply the tank with an electric heating system.

- Automation of varying complexity. Reverse and mixer timers are standard equipment. In the advanced, weight sensors and scales are added. The user himself monitors the scales and at the right time stops the flow of each ingredient. In a complete set, automation automatically remembers up to 9 multicomponent recipes and stops the crusher when a portion of the selected ingredient is collected.

|

Before deciding which modification of the feed mixer you should buy, we recommend that you consult our managers. They will provide all the necessary information about the configuration, delivery in country and abroad, current producer prices, etc.

* Attention. Product description can be obtained by machine translation.