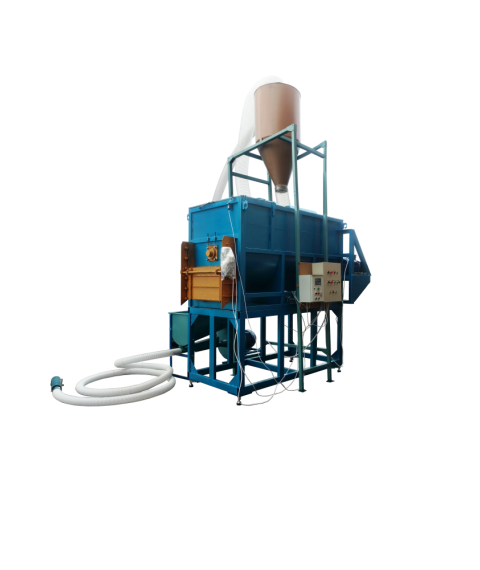

FEED MIXER 3 M3

| Seller | Artmash |

| Brand: | Artmash |

| Product Code: | ZK-3 |

| SKU : | ZK-3 |

-

Price on request

You can request a product via the "Contact with the seller" form.

| Seller | Artmash |

| Brand: | Artmash |

| Product Code: | ZK-3 |

| SKU : | ZK-3 |

You can request a product via the "Contact with the seller" form.

Model: ZK-3

Motor capacity: 11 kW

Hopper capacity: 3 m3

Yield capacity: 3,5 - 8 t/h

Weight: 2300 kg

Dimensions: 3523*1600*4600 mm

Mixer 3 m3 is designed for mixing up to 2 tons of feed of various recipes in one batch. The equipment can be purchased as part of a bulk feed plant (complete with a grinder) or separately. The mixer is also suitable for pelletizing lines for a variety of raw materials in the production of feed pellets and agricultural pellets.

This model is part of a range of horizontal mixer wagons with two counter-mixing elements. She retains the advantages inherent in other representatives of this series:

| Spur gearbox with a gear ratio of 1 to 100 | |

Together with an 11 kW motor, it generates a large torque, thanks to which the mixer efficiently handles any raw material and does not create a significant sound load. | |

| Automatic reverse, | |

| which changes the direction of rotation of the auger for better mixing of the feed. | |

| Electronic gate | |

| as in previous models, unloading is carried out at the end of the bunker. Thanks to this, when working in line, the mixture is poured directly into the feed screw. The gate was equipped with an electric drive and a separate button was brought to the control panel. | |

| The minimum distance between the turns of the mixer and the walls of the hopper | |

| The unloading takes place efficiently and there is no feed left in the container from the previous batch. |

There are several configuration options available for the 3 m3 mixer. To the basic tank with agitators and electronic gate you can add:

| ∴ | Aspiration system for dust removal We close the hopper with a lid with a sealing tape, connect a cyclone and 3 felt bags to filter dust. |

| ≥ | Automatic weighing system We will install strain gauges and connect automation to it, which remembers up to 9 recipes for 6 components. The system will control the filling of the hopper for each ingredient. |

| ≅ | Oil injection system Add spray nozzles to the hopper. The launch will be carried out from the control panel. |

If you need to discuss the modification of a 3 m3 mixer (for example, reduce the height), buy additional equipment for the old model, clarify the price or discuss delivery in the country and abroad, please contact our managers.