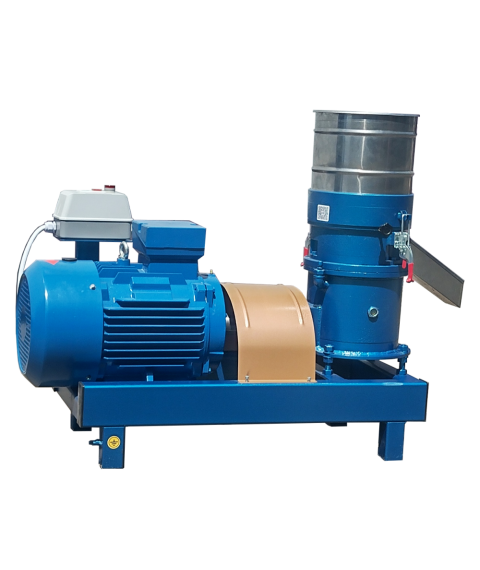

FUEL PELLET MILL 15 KW

| Seller | Artmash |

| Brand: | Artmash |

| Product Code: | GPP-15 |

| SKU : | GPP-15 |

-

117700.00₴

You can request a product via the "Contact with the seller" form.

| Seller | Artmash |

| Brand: | Artmash |

| Product Code: | GPP-15 |

| SKU : | GPP-15 |

You can request a product via the "Contact with the seller" form.

Pellet mill for the production of pellets from agricultural waste and sawdust for own use. Conical rollers. Reliable gearbox. French, Czech and Japanese bearings. 95% of parts are manufactured in-house.

Model: GPP-15

Voltage: 400 V

Motor capacity: 15 kW, 1000 revolutions

Yield capacity:

Pellet diameter: 2-8 mm

Pellet mill weight: 250 kg

Dimensions:1050х400х1000 mm

Die diameter: 230 mm

The model is used as part of a mini-line for the production of fuel pellets in farms and woodworking workshops. It is also possible to manufacture granules for soil fertilization.

An engine with a power of 15 kW, 1000 revolutions granulates sawdust, straw, seed husks, sunflower waste ... In order for the granule to turn out to be solid, without bumps and cracks, the moisture content of the raw material should not exceed 14%.

| ¤ | Asynchronous motor circuit breaker with electromagnetic thermal protection prevents motor damage due to network problems or solid objects entering the hopper. |

| ¤ | The granulator accommodates a hypoid helical gear. This achieves a significantly lower noise level during operation and increases the service life of the gearbox (compared to a spur gear). |

| ¤ | An electronic ammeter helps the operator to monitor the condition of the equipment and set the maximum allowable supply of raw materials. |

To increase productivity by 15-20%, we recommend working with a fine loading auger. He will help:

| ∗ | reduce wear of rollers, matrix, bearings; |

| ∗ | evenly distribute the load on the motor; |

| ∗ | prevent engine overheating; |

| ∗ | minimize user effort. |

For this model, we recommend a screw with a 0.6 cubic metre hopper and automatic feed control (STP-0.6), but to save space, it is possible to use a variant with a 220 litre hopper (DGM-220).

Before making the final selection of the auger, it is important to check the stability of the power grid, since only the pelletizer requires a rated current of 32A.

| ☑ | Allows you to get 20% more pellets compared to straight rollers. |

| ☑ | They allow you to save on dies, replacing them 2.5 times less often. |

| ☑ | They do not degrade the quality of the pellets, even when the teeth on the rims are almost worn off. |

| ☑ | They need to be replaced 2-2.5 times less often than straight rollers. |

| ☑ | No maintenance required. The lubricant provided at the factory protects the mechanism until the teeth on the rims are worn out. |

| ☑ | Reduce energy costs by increasing the energy efficiency of the equipment. |

| ☑ | Increase the maintenance-free life of the pellet mill, as the equipment operates in the most efficient mode. |

The resulting pellets fully comply with European standards and are suitable for use with all types of pellet boilers.

If you want to save on heating and efficiently dispose of your own company's waste, you should purchase GPP-15 at the manufacturer's price.

To order a pellet granulator 15 kW, 380 V, please contact the managers of Artmash LLC. Guarantee 12 months, in addition, we provide post-warranty service for local and foreign customers.

We carry out delivery of goods to any region of Ukraine. Our equipment complies with international quality standards, so we send it abroad (more than 20 countries) directly to the consumer or through a dealer.