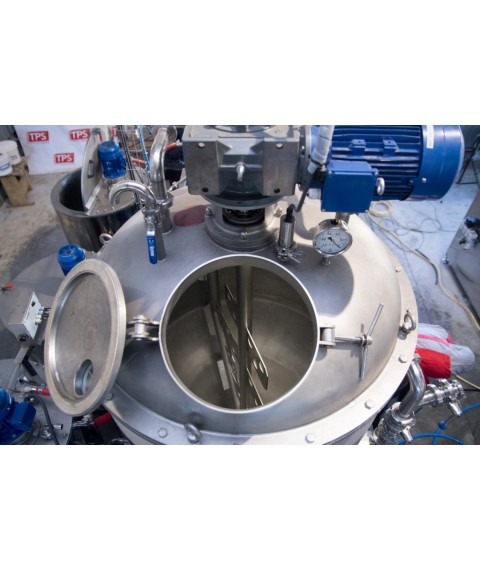

PURPOSE: - Universal vacuum units LKS are intended for preparation of ketchups, sauces and other food products in vacuum conditions. - For the production of high-quality products with a long shelf life without the use of preservatives and stabilizers. - Line productivity from 500 to 2500 kg/h. ARE USED FOR PREPARING PRODUCTS: - ketchups and sauces without inclusions; - ketchups or sauces with inclusions, such as lecho, bulgarian, adjika, tkemali, etc.; - mustard and any other food products. The main operations occurring in the cooking process: - absorption of fluid products (dry and liquid) under vacuum; ? - mixing of liquid and dense products; ? - dispersion of dry components in liquids; - obtaining emulsions; - evaporation of excess moisture, normalization of dry matter content; ? - removal of gases from a product in the vacuum mode. ADVANTAGES: ? - Plant control by PLC, possibility to create and save working programs (recipes). ? - Product recirculation system and deaeration mode. ? - Before introducing pieces of vegetables, spices or filler, the product is subjected to a homogenization process - to improve the structure, increase viscosity and prevent product delamination; ? - Systems of high-precision dosing of ingredients. ? - Components of the world's leading manufacturers. For more information about this offer, follow the link OUR CONTACTS: Kherson, st. 9th Vostochnaya, 5 tel.: +38 (067) 552-1110 tel.: +38 (067)553-1402 ? - Product recirculation system and deaeration mode. ? - Before introducing pieces of vegetables, spices or filler, the product is subjected to a homogenization process - to improve the structure, increase viscosity and prevent product delamination; ? - Systems of high-precision dosing of ingredients. ? - Components of the world's leading manufacturers. For more information about this offer, follow the link OUR CONTACTS: Kherson, st. 9th Vostochnaya, 5 tel.: +38 (067) 552-1110 tel.: +38 (067)553-1402 ? - Product recirculation system and deaeration mode. ? - Before introducing pieces of vegetables, spices or filler, the product is subjected to a homogenization process - to improve the structure, increase viscosity and prevent product delamination; ? - Systems of high-precision dosing of ingredients. ? - Components of the world's leading manufacturers. For more information about this offer, follow the link OUR CONTACTS: Kherson, st. 9th Vostochnaya, 5 tel.: +38 (067) 552-1110 tel.: +38 (067)553-1402 For more information about this offer, follow the link OUR CONTACTS: Kherson, st. 9th Vostochnaya, 5 tel.: +38 (067) 552-1110 tel.: +38 (067)553-1402 For more information about this offer, follow the link OUR CONTACTS: Kherson, st. 9th Vostochnaya, 5 tel.: +38 (067) 552-1110 tel.: +38 (067)553-1402

sales@tavrproms.com

www.tavrproms.com YouTube

* Attention. Product description can be obtained by machine translation.